THERMAL TRANSFER OVERPRINTER (TTO)

Thermal Transfer Overprinting (TTO) is a technology that creates images in high-definition by pushing a ribbon into contact with a substrate using a printhead.

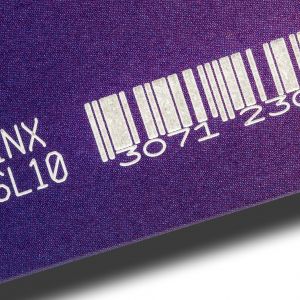

Thermal transfer printers, functional in either continuous or intermittent printing modes, can print at very high resolution print quality and on fast moving production lines.. Print a series of messages, including pricing, date and time coding, barcodes, QR codes, logos, ingredients lists or even marketing messages.